INDUSTRIAL AUTOMATION

Project

In industry, easy and reliable production and management are fundamentally possible through the proper operation of the process and control at every stage. When planning such a process, automation will be the best assistant to ensure more controlled and higher quality production with less manpower.

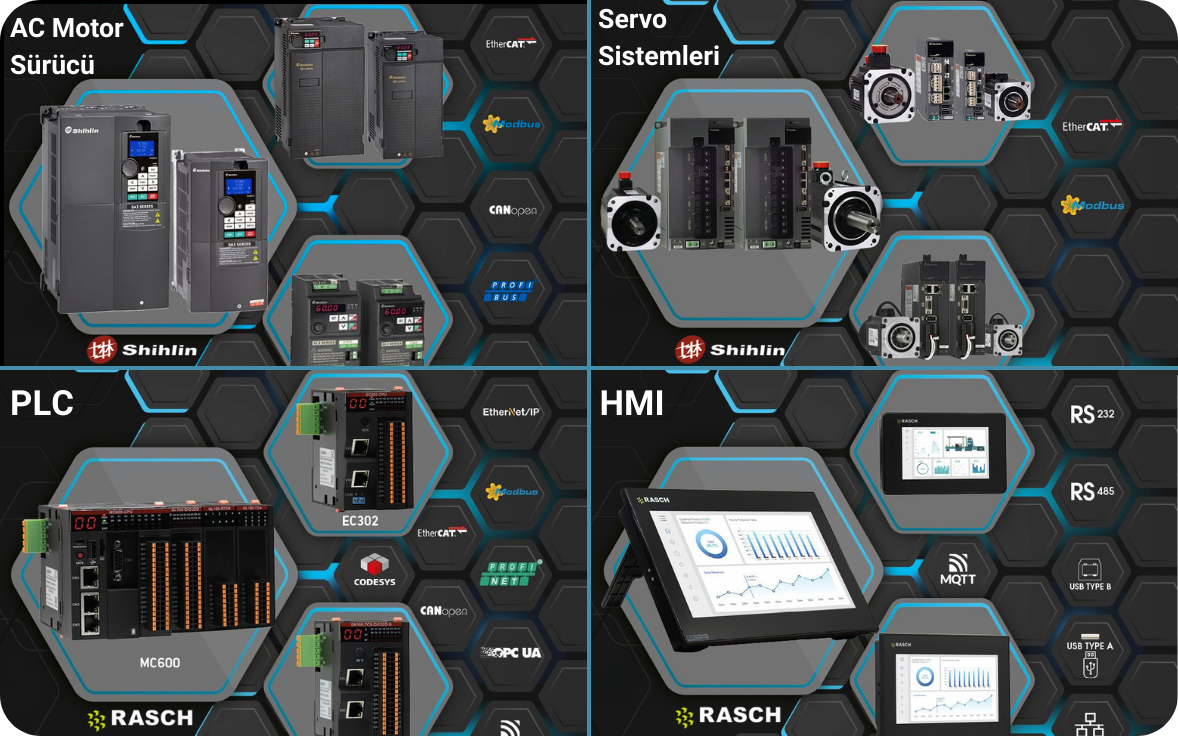

You can use the form below for your PLC, HMI, AC Drive, Servo Control, and CODESYS 3.5 applications and machine automation projects.